Edge Grain vs End Grain: Which Cutting Board Lasts Longer?

When choosing between edge grain and end grain boards, consider fiber orientation: edge grain has parallel fibers, offering durability and affordability with visible knife marks.

End grain features vertical fibers that self-heal, absorb impact, and keep knives sharper longer.

Edge grain boards resist moisture better with less upkeep, but end grain excels in heavy chopping and longevity despite higher maintenance.

Both differ in cost, fabrication complexity, and hygiene. Keep exploring to find which fits your kitchen tasks best.

- EDGE GRAIN CUTTING BOARDS: THE CLASSIC CHOICE — Built for daily use, this edge grain wood cutting…

- PREMIUM TEAK: EXCEPTIONAL DURABILITY & WATER RESISTANCE — Treasured for its rich, golden-brown…

- MESS-FREE COUNTERS WITH DEEP JUICE GROOVE — Slice the juiciest meats or ripe fruit without the…

- PREMIUM END GRAIN ACACIA WOOD CUTTING BOARD known for its rich colors with beautiful contrasting…

- MULTI-FUNCTIONAL BOARD serves as a prep station cutting and serving board for vegetables meat cheese…

- DURABLE END GRAIN WOOD CONSTRUCTION minimizes wear and tear on both cutlery and board for long…

Key Takeaways

- Edge grain boards have fibers running lengthwise, offering durability and easier maintenance but show visible knife marks and dull knives faster.

- End grain boards feature vertical fiber orientation, providing superior impact resistance and self-healing surfaces that preserve knife sharpness longer.

- End grain’s mosaic pattern hides imperfections and offers a unique aesthetic, while edge grain provides a smoother, uniform hardwood-flooring appearance.

- Edge grain is more cost-effective and faster to produce, whereas end grain requires more material, labor, and frequent oiling for maintenance.

- End grain boards absorb moisture more readily, needing careful upkeep to prevent warping, while edge grain resists moisture better with less maintenance.

At a Glance: Comparing Edge Grain and End Grain Boards

| Feature | Edge Grain | End Grain |

|---|---|---|

| Grain Orientation | Fibers run lengthwise, forming smooth parallel lines | Fibers are vertical, forming a checkerboard pattern |

| Durability | Moderately durable, resists moisture well but shows knife marks | Highly durable, absorbs impact and resists deep cuts |

| Knife Friendliness | Cuts across fibers, dulling blades faster | Knives cut between fibers, staying sharper longer |

| Maintenance | Requires less frequent oiling and easy cleaning | Needs regular oiling every few weeks to prevent drying |

| Moisture Resistance | Better resistance due to tight grain alignment | Higher absorption, requires more care to avoid warping |

| Visual Appeal | Uniform, linear grain with sleek appearance | Mosaic-like pattern that hides scratches and adds character |

| Weight & Handling | Lighter and easier to move | Heavier and thicker, more stable during chopping |

| Manufacturing Complexity | Simple fabrication, fewer joints, faster production | Intricate process, requires precise alignment and labor |

| Cost Factor | More affordable due to efficient production | Higher cost for craftsmanship and material use |

| Ideal Use Case | Great for light chopping and serving | Best for heavy chopping and professional kitchens |

Understanding Wood Grain Orientation

Although wood grain orientation might seem subtle, it fundamentally determines the wood’s mechanical properties and appearance by defining the direction in which the fibers align relative to the tree’s axis.

Wood grain orientation subtly shapes both the strength and beauty of timber by aligning fibers along the tree’s axis.

You’ll find grain types like straight, spiral, wavy, interlocked, and irregular, each influencing strength, stability, and aesthetics. Each board from the same species can exhibit a unique grain pattern, making every piece distinct.

The grain’s direction results from tree growth patterns and the sawing method used. For example, straight grain runs parallel to the axis, delivering uniform strength, while spiral or interlocked grains create complex patterns but may affect predictability.

Grain orientation impacts how wood handles moisture, shrinking more tangentially than radially, which directly influences warping and cracking risks. Proper maintenance, like regular sharpening, is essential in woodworking tools to maintain optimal performance when working with different grain types.

Comparing Durability and Knife Friendliness

When selecting a cutting board, understanding the differences in durability and knife friendliness between edge grain and end grain constructions is essential for optimizing both board longevity and blade maintenance. Edge grain boards offer solid durability and resist moisture well but show visible knife marks and don’t self-heal, causing faster wear. They are also more affordable and lighter, making them easier to handle and serve from. Additionally, selecting materials with proper thickness and finish can improve durability and ease of cleaning, key factors noted in kitchen lighting considerations.

In contrast, end grain boards feature thick, robust construction with wood fibers oriented to self-repair cuts, markedly extending lifespan. Regarding knife friendliness, end grain boards preserve blade sharpness by allowing knives to cut between fibers, reducing dulling and sharpening frequency. Edge grain boards cut through fibers directly, dulling knives faster though still outperforming plastic or glass. Choosing between these depends on balancing durability needs and blade preservation, with end grain favored for heavy use and edge grain for moderate, moisture-rich tasks.

Maintenance Requirements and Longevity

Since maintenance directly influences cutting board lifespan, understanding the differing care demands of edge grain and end grain boards is essential.

Edge grain boards require less frequent oiling, typically needing treatment less often than end grain boards. This is similar to how temperature regulation ensures consistent results with less frequent intervention.

End grain boards demand oil application every 6 to 8 weeks due to their higher absorbency.

You’ll need to elevate end grain boards during drying to prevent moisture buildup and warping, while edge grain boards dry evenly with standard methods.

Regular application of mineral oil or board balm is critical for both, sealing the wood and preventing cracking.

Neglecting maintenance on end grain boards accelerates degradation, though their self-healing fibers reduce visible knife damage.

Edge grain boards maintain shape better over time, but end grain boards, with proper upkeep, offer superior longevity and knife-edge preservation.

Cost Differences and Manufacturing Complexity

End grain boards really require a lot of intricate work. You’re looking at precise cutting and aligning a bunch of small wood blocks, which definitely ramps up both the labor intensity and material waste. It’s quite a process, to say the least! Additionally, the wood fibers in end grain boards stand vertically, resembling a microscopic bamboo forest, which contributes to their unique durability and cutting properties wood grain direction.

Now, when we switch gears to edge grain boards, it’s a whole different story. They use longer planks, and the assembly is much simpler. This means production time and resource consumption are both reduced, making it a more straightforward option.

Fabrication Process Complexity

Although both edge grain and end grain boards serve similar functions, their fabrication processes differ considerably in complexity and cost.

Edge grain boards involve gluing long wood strips with parallel grains, which simplifies cutting, alignment, and adhesive application. This results in an overall more budget-friendly product due to the simpler manufacturing. Their production benefits from efficiency in manufacturing similar to how dehydrators promote even heat circulation through proper rotation.

End grain boards demand assembling numerous small blocks with perpendicular grains, requiring high-precision cutting, specialized jigs, and more glue joints.

| Aspect | Edge Grain | End Grain |

|---|---|---|

| Cutting & Assembly | Simple, large strips, fewer joints | Complex, many small blocks, many joints |

| Tooling & Labor | Standard tools, less skilled labor | Specialized jigs, skilled labor |

| Production Speed | Faster, scalable | Slower, limited throughput |

Material Usage Impact

Understanding the fabrication complexity gives insight into how material usage directly impacts cost and manufacturing efficiency.

When you choose edge grain boards, you benefit from longer, continuous wood strips, minimizing waste and optimizing material yield. End grain boards, however, require numerous small blocks, increasing scrap and raw material demands. This difference influences both your upfront material costs and the complexity of sourcing.

Edge grain fabrication utilizes standard lumber lengths, simplifying procurement and reducing wood consumption. Additionally, edge grain uses the side of the wood pieces for the cutting surface, which affects how boards are cut and assembled. This is similar to how the choice of material durability impacts the longevity and maintenance of kitchen sinks.

End grain’s higher scrap rate demands more expensive wood species, raising raw material expenses.

Edge grain boards’ greater susceptibility to wear can lead to more frequent replacements, indirectly affecting lifetime material use.

Price Variation Reasons

Because end grain cutting boards require intricate craftsmanship and extensive labor, their price often exceeds that of edge grain boards.

You’ll spend more due to the complex cutting of small wood blocks and precise vertical fiber alignment, which lengthen fabrication time. This process is similar in complexity to creating a multi-step roux in cooking, where precision impacts the final quality.

The multi-step milling, sanding, and finishing processes demand skilled labor and specialized equipment, adding overhead costs.

Material waste is higher since end grain production cuts wood into numerous small pieces, and selecting defect-free blocks raises raw material expenses.

Thicker slabs increase wood volume requirements, further inflating costs.

Additionally, end grain boards are typically heavier due to their size and density, which affects portability and handling.

In contrast, edge grain boards use longer horizontal strips with simpler cuts, reducing both labor and material waste.

Visual Appeal and Design Characteristics

When you examine the visual appeal of cutting boards, end grain and edge grain present distinctly different design characteristics that influence both aesthetics and functionality.

End grain displays a checkerboard pattern formed by cross-sectioned wood fibers, which creates a dense, mosaic-like surface with variegated color due to visible pores and growth rings. This pattern also contributes to its high durability. Additionally, end grain boards are known for being gentler on knives, preserving blade sharpness over time.

Edge grain shows long, parallel grain lines resembling hardwood flooring, offering a smooth, uniform appearance with lighter, consistent coloration. Edge grain boards often require less maintenance compared to end grain, making them a practical choice for busy kitchens.

The tactile experience differs too: end grain feels softer and absorbs finish more deeply, while edge grain is smoother and achieves a glossy finish easily.

End grain’s segmented design conceals imperfections and adds character over time.

Edge grain emphasizes wood continuity and highlights lumber quality.

End grain’s pattern density contrasts with edge grain’s linear simplicity.

Practical Use Cases for Each Grain Type

Although both edge grain and end grain wood have distinct structural properties, their practical applications vary considerably based on durability, maintenance, and cost factors.

You’ll find edge grain ideal for kitchen countertops, workbenches, and flooring due to its affordability, resistance to cupping, and easier maintenance. It suits cabinetry and tabletops where straight grain and cost-effectiveness matter. Its simpler construction process also contributes to the lower costs and ease of repair. Placing these surfaces on a stable surface ensures longer lifespan and safety in use.

Conversely, end grain excels in commercial settings like heavy-duty flooring and professional kitchen cutting boards. It offers superior impact resistance and self-healing qualities.

It demands more frequent oiling and deeper maintenance to prevent drying and cracking.

While edge grain is less expensive and simpler to produce, end grain’s complexity raises costs but guarantees longer surface integrity under heavy use.

Impact on Knife Sharpness and Performance

When you cut on an end-grain board, something interesting happens. The knife edge interacts with vertical fibers that flex a bit. This flexing helps preserve the sharpness of your knife by minimizing edge wear. Pretty cool, right? End grain boards also compress slightly upon contact, reducing strain and friction on knife edges, which helps knives stay sharper longer. Using end-grain surfaces can be compared to having an Impact-absorbing surface.

Now, if you switch to an edge-grain board, things change. Here, the fibers are horizontal, and the blade has to sever them. This can actually increase friction and cause some microscopic damage over time. Edge grain boards are more affordable and lower maintenance, making them popular for everyday use despite the increased friction.

Knife Edge Preservation

How does the choice between end grain and edge grain cutting boards affect your knife’s sharpness and longevity?

End grain boards preserve knife edges better by allowing the vertical wood fibers to absorb blade impact, reducing dulling. These boards self-heal, closing knife marks and minimizing blade wear, which means you’ll sharpen less frequently. Additionally, the self-healing property of end grain boards contributes to their durability and long-term performance. Proper maintenance, similar to knife edge preservation, ensures these boards remain effective over time.

Edge grain boards, conversely, cause knives to dull 20-30% considerably faster since cuts slice through wood fibers, increasing edge degradation.

Consider these points for knife edge preservation:

- End grain boards can halve your knife sharpening frequency over time.

- Edge grain boards need less maintenance but accelerate blade dulling.

- Wood type combined with grain orientation significantly influences edge longevity and board performance.

Choosing end grain with a suitable wood like hard maple optimizes your knife’s sharpness and lifespan.

Cutting Surface Interaction

Selecting between end grain and edge grain cutting boards doesn’t just influence how often you’ll need to sharpen your knives. It also affects how your blade interacts with the cutting surface during use.

End grain boards present fibers perpendicular to the blade, letting your knife slide between them. This lowers cutting resistance and minimizes edge damage. The “bundle of straws” fiber structure also self-heals, maintaining a smoother surface and reducing friction. Additionally, end grain cutting boards are highly durable and can absorb impacts well, which helps protect knife edges over time due to their impact absorption.

In contrast, edge grain boards expose fibers parallel or angled to the surface. This forces your blade to cut across fibers, increasing friction and accelerating wear. This orientation can cause micro-chipping and faster dulling as your knife encounters more resistance.

Blade Wear Differences

Although both end grain and edge grain boards serve as functional cutting surfaces, their impact on blade wear differs markedly due to fiber orientation and surface characteristics.

On end grain boards, knives cut between wood fibers, notably reducing blade wear and preserving sharpness longer. Conversely, edge grain boards expose long fibers, causing knives to cut across them, which accelerates dulling.

The self-healing fibers of end grain wood close after cuts, cushioning the blade and maintaining cutting efficiency. Edge grain boards lack this property, leading to increased microscopic chipping and more frequent sharpening.

End grain boards reduce friction and blade edge degradation by allowing knife edges to glide between fibers. This type of board also requires regular oiling to maintain its protective qualities and prevent drying or warping.

Edge grain surfaces increase blade wear due to cutting across longer, exposed fibers.

Hygiene Considerations and Food Safety

When you consider hygiene and food safety, the structural differences between edge grain and end grain cutting boards play a critical role in bacterial entrapment and cleaning effectiveness.

End grain boards expose wood fibers vertically, enabling knife cuts to separate rather than sever fibers. This limits deep scoring and reduces bacterial harborage in grooves. Additionally, hardwoods like maple and walnut commonly used in end grain boards have natural antimicrobial properties that enhance board hygiene.

End grain boards minimize deep cuts by separating wood fibers, reducing places for bacteria to hide.

In contrast, edge grain boards’ parallel fibers are severed by knives, creating visible gouges that trap food particles and microbes. This increases contamination risks if not meticulously cleaned.

Both board types possess inherent antimicrobial properties, but damage level directly affects bacterial residency.

You must perform routine cleaning and maintenance, especially frequent oiling for end grain, to preserve surface integrity and reduce pathogen survival.

Designate boards for specific food types to prevent cross-contamination, as hygiene best practices override grain choice in food safety.

Moisture Resistance and Warping Potential

How does the grain orientation of a cutting board influence its resistance to moisture and susceptibility to warping?

Edge grain boards feature densely packed fibers running lengthwise, which resist moisture penetration and minimize warping risks. Their quarter-sawn construction offers superior moisture evaporation and structural stability under varying conditions.

Conversely, end grain boards expose vertical fibers that absorb some moisture, necessitating frequent oiling to prevent drying and warping. Their block construction can trap moisture between joints, increasing deformation risk despite self-healing fibers.

Consider these factors: Edge grain’s tight fiber arrangement improves moisture resistance and reduces warping. End grain’s vertical fibers absorb water but enhance impact durability. Proper maintenance, especially oiling and drying, is critical for end grain stability.

Choosing the Right Board for Your Kitchen Needs

Understanding the moisture resistance and warping tendencies of edge grain and end grain boards sets the foundation for selecting the right cutting board tailored to your kitchen demands.

Knowing how edge and end grain boards resist moisture and warp helps you pick the perfect cutting board.

If you prioritize durability, end grain boards excel due to their vertical wood fibers that absorb knife impacts and self-heal. This makes them ideal for heavy chopping and frequent use.

However, they require more maintenance, including regular oiling, and come at a higher price with increased weight.

Conversely, edge grain boards offer a cost-effective, lighter option with lower maintenance needs.

They are suitable for lighter cutting tasks and serving.

Edge grain boards show wear faster and dull knives quicker, but their uniform grain and affordability make them practical for everyday use.

Choose based on your usage intensity, maintenance willingness, and aesthetic preference.

Frequently Asked Questions

Can End Grain Boards Be Refinished at Home Without Professional Tools?

Yes, you can refinish end grain boards at home without professional tools.

Use a random orbital sander or sanding blocks with progressively finer grits, starting coarse (60-80 grit) and moving up to fine (up to 600 grit).

Hand sanding works but takes longer.

Clean thoroughly between grits, apply mineral oil and beeswax blends for finishing, and reapply regularly.

Protect yourself with a mask during sanding and avoid harsh finishes that form plastic layers.

Are Edge Grain Boards Better for Cutting Acidic Foods Like Lemons?

Yes, edge grain boards handle acidic foods like lemons like a fortress withstands a storm.

Their tight grain orientation reduces porosity, limiting acid and moisture absorption that causes staining and wood degradation.

You’ll find they resist discoloration and warping better, maintaining surface integrity longer.

Plus, they need less frequent oiling and are easier to clean, making them a practical choice when you regularly cut acidic ingredients.

How Do Temperature Changes Affect End Grain Versus Edge Grain Boards?

You’ll find end grain boards more vulnerable to temperature fluctuations since their porous fibers absorb and lose moisture rapidly, causing swelling, shrinking, and potential cracking.

Cold, dry air especially accelerates moisture loss in end grain, risking surface checks.

In contrast, edge grain boards resist these changes better due to lower porosity, maintaining dimensional stability and reducing warping.

You’ll need to oil end grain boards more often during temperature swings to preserve their integrity.

Is It Safe to Use Both Types Interchangeably for Raw Meat and Vegetables?

Yes, you can use both types interchangeably for raw meat and vegetables, but safety hinges on your cleaning habits. Both boards absorb juices, so you must clean and sanitize them promptly after use to prevent bacterial growth.

Using separate boards or rigorous sanitation reduces cross-contamination risk. Remember, end grain needs more frequent oiling to maintain integrity, while edge grain cleans easier.

Proper maintenance and hygiene are key to safe, versatile use.

Can Edge Grain Boards Be Customized With Inlays or Engravings Easily?

You can customize edge grain boards with inlays or engravings as easily as snapping your fingers! Their flat, stable surface lets you cut precise channels for inlays made from wood, metal, or resin.

Laser or rotary engravings achieve detailed, consistent depths without splitting the wood. The consistent grain direction guarantees strong glue adhesion.

Finishing steps like sealing and sanding protect your custom work, keeping it durable and visually stunning.

Edge Grain or End Grain: Striking the Ideal Balance Between Strength and Blade Care

When choosing between edge grain and end grain, consider durability versus knife friendliness, maintenance versus longevity, cost versus manufacturing complexity, and visual appeal versus performance impact.

Edge grain boards offer affordability and straightforward upkeep, while end grain boards provide superior knife preservation and moisture resistance.

By weighing these factors carefully, you’ll select the cutting board that best fits your kitchen demands, ensuring ideal functionality, hygiene, and long-term satisfaction with every meal you prepare.

- LONG LASTING DURABLE EDGE GRAIN ACACIA: Our Acacia Edge Grain Cutting Boards are built of durable…

- LARGE SURFACE, REVERSIBLE, VERSATILE: Cut, chop, and dice on this edge grain acacia wood cutting…

- DEEP JUICE GROOVE, BUILT-IN HANDLES: Say Goodbye to Mess countertop. Our chopping board features a…

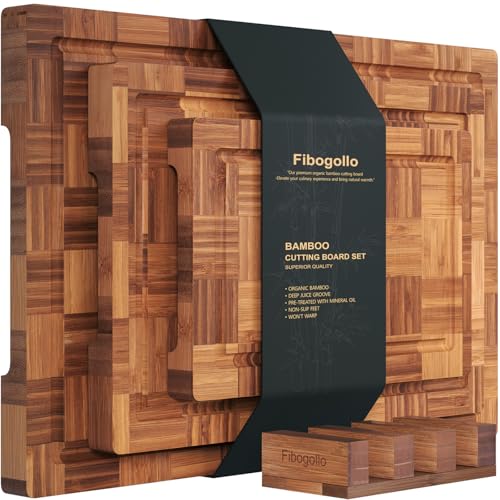

- 【Splicing Craft,Innovative Design】This chopping board features a bamboo unique splicing craft…

- 【Natural Bamboo Material】Crafted from high-quality natural bamboo,each piece is meticulously…

- 【Bamboo Cutting Boards with Mineral Oil Treatment】 This bamboo cutting board is pre-treated with…

Last update on 2026-02-28 / Affiliate links / Images from Amazon Product Advertising API